Four Popular Electric Vehicle Battery Vibration Testing Profiles

Lithium-ion batteries are gaining popularity as the most common battery type used for electric vehicles. During their lifespan, these batteries undergo a variety of vibrations and temperature changes. Several common test standards have developed to simulate the long-term environmental effects on these batteries across different size levels (e.g. cell, module, pack).

Of the many test standards for EV batteries, this post will specifically focus on the vibration and temperature aspects of four well-known standards: SAE J2380, SAE J2464, IEC 62660-2, and UN 38.3.

Crystal Instruments Spider systems can provide solutions for random, sine, and shock vibration test, as well as temperature control.

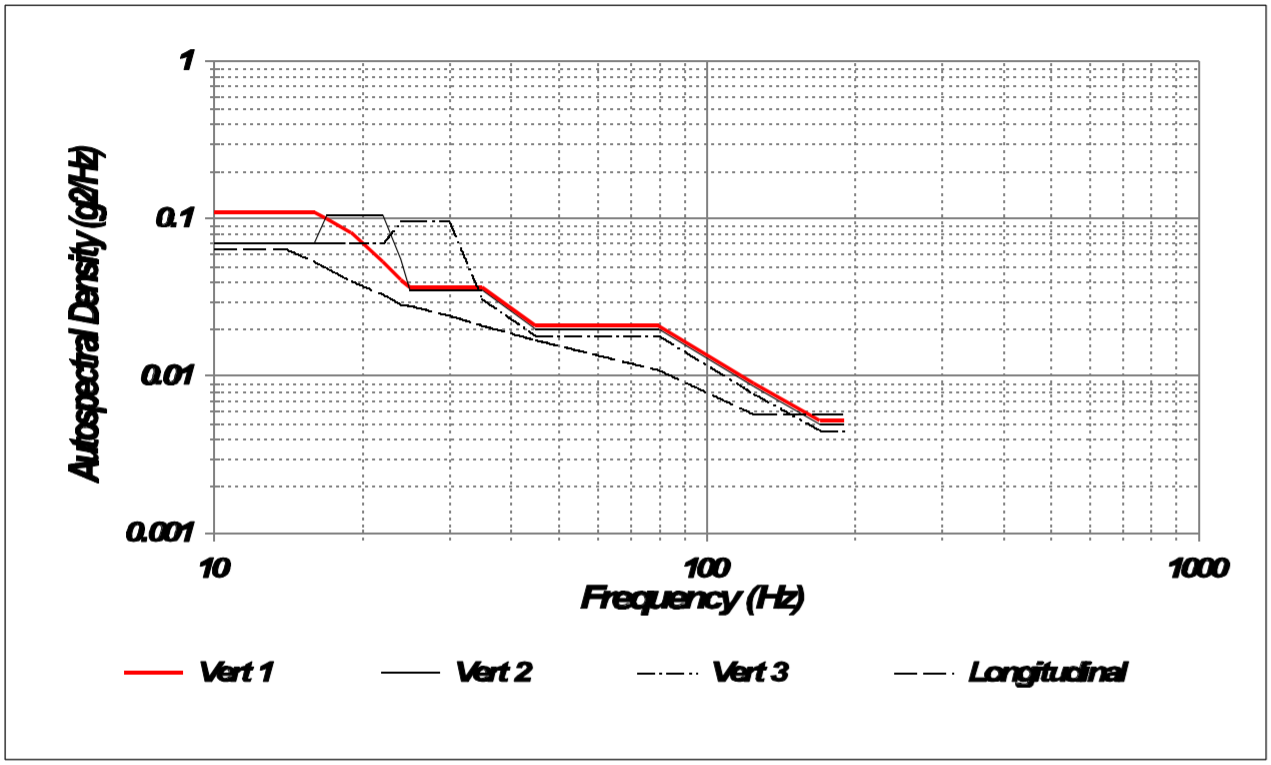

SAE J2380 Random Test Profile

SAE J2380

The SAE J2380 standard vibration profiles, based off of actual road measurement data, intends to simulate the effect of driving 100,000 miles on battery packs and modules. The standard calls for a series of random vibration profiles, to be applied across all three perpendicular axes for time periods ranging from 9 minutes to 38 hours each.

SAE J2464 Half-Sine Shock Profile (rendered on EDM)

SAE J2464

The SAE J2464 standard evaluates abuse tolerance for cells and battery packs, performed to measure the response for any RESS (rechargeable energy storage system). These abuse scenarios are purposefully contrary to the battery's design intent, but can be expected to occur infrequently during field use (i.e. due to negligence, accidents, poor training, etc.)

Of all the test types listed, there are 2 specified test types for thermal shock cycling and shock vibration test. The thermal shock cycling consists of 5 cycles through hot and cold temperatures (70°C to -40°C) with each cycle length for 1 hour at the cell level, 6 hours at the module level. The shock vibration test applies 3 positive and 3 negative direction half-sine shocks in each of the three perpendicular axes.

IEC 62660-2

The IEC 62660-2 standard, also associated with ISO 12405, specifies reliability and abuse testing for electric vehicle lithium-ion cells for use in a variety of battery systems. The vibration test calls for a random vibration test for 8 hours on each plane of the cell, as well as a mechanical shock test (half-sine) in all six spatial directions. The temperature test starts the cell at room temperature, and raises the temperature at 5 K/min until reaching a final temperature of 130°C, staying within 2 K of that target temperature for 30 min. The thermal cycling test calls for 30 test cycles (85°C to -40°C).

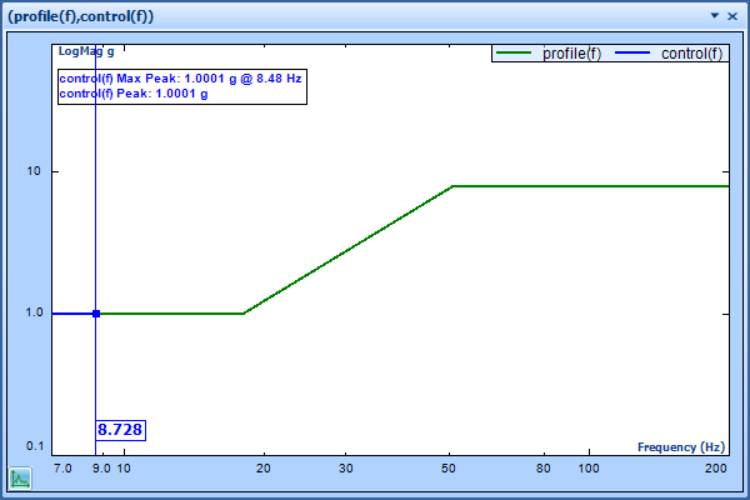

UN 3.3 Swept Sine Profile (rendered on EDM)

UN 38.3

The UN Manual of Tests and Criteria provides information on the test procedures for transporting dangerous goods, with section 38.3 discussing lithium ion batteries. Lithium-ion batteries must pass these tests before being cleared for transport.

Of the 8 total test types listed in the standard, there are 3 specified test types for thermal, vibration, and shock. The thermal test consists of 10 cycles through hot and cold temperatures (72°C to -40°C), followed by 24 hour storage at ambient temperature (20°C). The vibration test simulates the typical vibrations with transporting batteries with a swept sine test over 3 hours for each of the three possible perpendicular mounting positions. The shock test applies 3 positive and 3 negative direction half-sine shocks in each of the three perpendicular mounting positions (totaling to 18 shocks).