Machine Vibration Monitoring

Devices & Systems

Route Based Vibration Data Collector

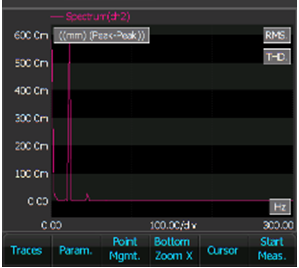

The CoCo hardware platform supports two different software working modes: Dynamic Signal Analyzer (DSA) and Route and OnSite Mode. Each working mode has its own user interface and navigation structure. DSA mode is designed for mechanical structure analysis, testing and optimization, electrical, geophysics, and a wide range of other applications. Route and OnSite Mode is dedicated to route-based machine condition monitoring, vibration data collection, and trending.

Remote Condition Monitoring Software

Remote Condition Monitoring (RCM) by Crystal Instruments is designed for the remote monitoring of equipment or structures that are inaccessible to configure within a local network. Common applications and examples of remote condition monitoring include the monitoring of vibrations during the transportation of equipment, monitoring vibrations on bridges and structures close to rails or roadways, and monitoring vibrations caused by rotating windmills on the ground.

Vibration Diagnostics System

The Vibration Diagnostic System (VDS) is a vibration data management system designed specifically for the Machinery Predictive Maintenance (PdM) community. It harnesses the graphic display capabilities of Crystal Instruments EDM Software for the work of machinery vibration analysts. It allows the user to quickly get to the data for a machine of interest and display that data in the familiar Tri-axial or Single Axis view. It lets users quickly compare to other data from the same machine, quickly navigate back into the historical data of the machine, and quickly compare the data to that of other machines in the database.

Spider-80X Machine Condition Monitoring System

The compact Spider-80X combined with EDM Cloud is designed for machine condition monitoring. With EDM Cloud, the test and the test engineer can literally be oceans apart. Applications include machine conditioning monitoring, wind turbine vibration and status monitoring, bridge and railway vibration monitoring, tunnel sound monitoring and more.