What is Vibration Testing?

Vibration and shock testing is a type of environmental testing where the test object is fixed to a shaker system and subjected to controlled vibrations meant to mimic what the object might encounter out in the field. The three most common types of vibration tests are Random, Sine and Shock.

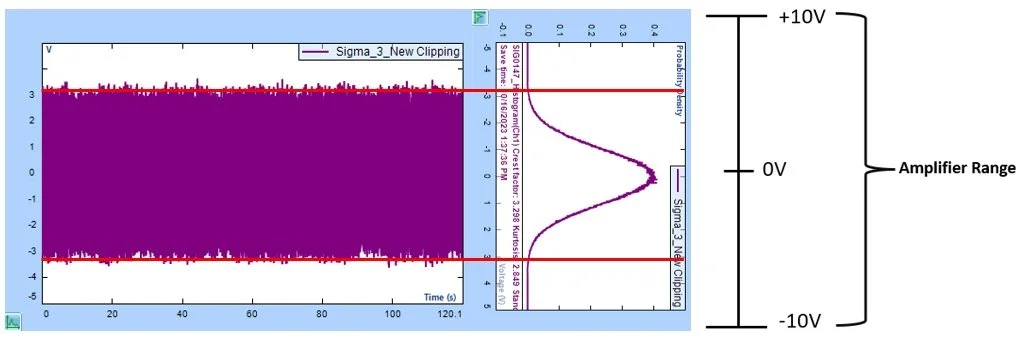

Random Vibration Testing

A Random vibration test will excite all frequencies across a given range (say 5 Hz to 2000 Hz) according to a target profile defined by the customer. These profiles are often defined as a plot of frequency vs amplitude in terms of a breakpoint table. Alternatively, recording data taken from the field (e.g., an accelerometer attached to component undergoing vibrations) can be processed using fatigue damage theory to generate a Random vibration profile of comparable damage.

Random Vibration Test

Sine Vibration Testing

A Sine vibration test will only excite one frequency at a given time. The voltage drive used to excite the shaker system will be shaped like a sine wave. Sine tests can either dwell (frequency does not change), or sweep (frequency changes with time, usually a logarithmic of linear sweep). For sine sweeps, the measured Sine spectrum is an aggregate plot built over time as the sine sweeps across a frequency range.

Sine Vibration Test

Shock Vibration Testing

A Shock vibration test is defined in the time domain and simulates an impulse that happens in a very short amount of time (i.e., one second or shorter). The intensity of a shock pulse can be characterized as a Shock Response Spectrum (SRS) which plots the peak response of a hypothetical spring-mass (i.e., single-degree-of-freedom or SDOF) system against the SDOF system’s natural frequency. Shock pulses can be defined with either common mathematical functions (e.g., half-sine) or synthesized as the sum of multiple component pulses to meet a target SRS.

Shock Vibration Test

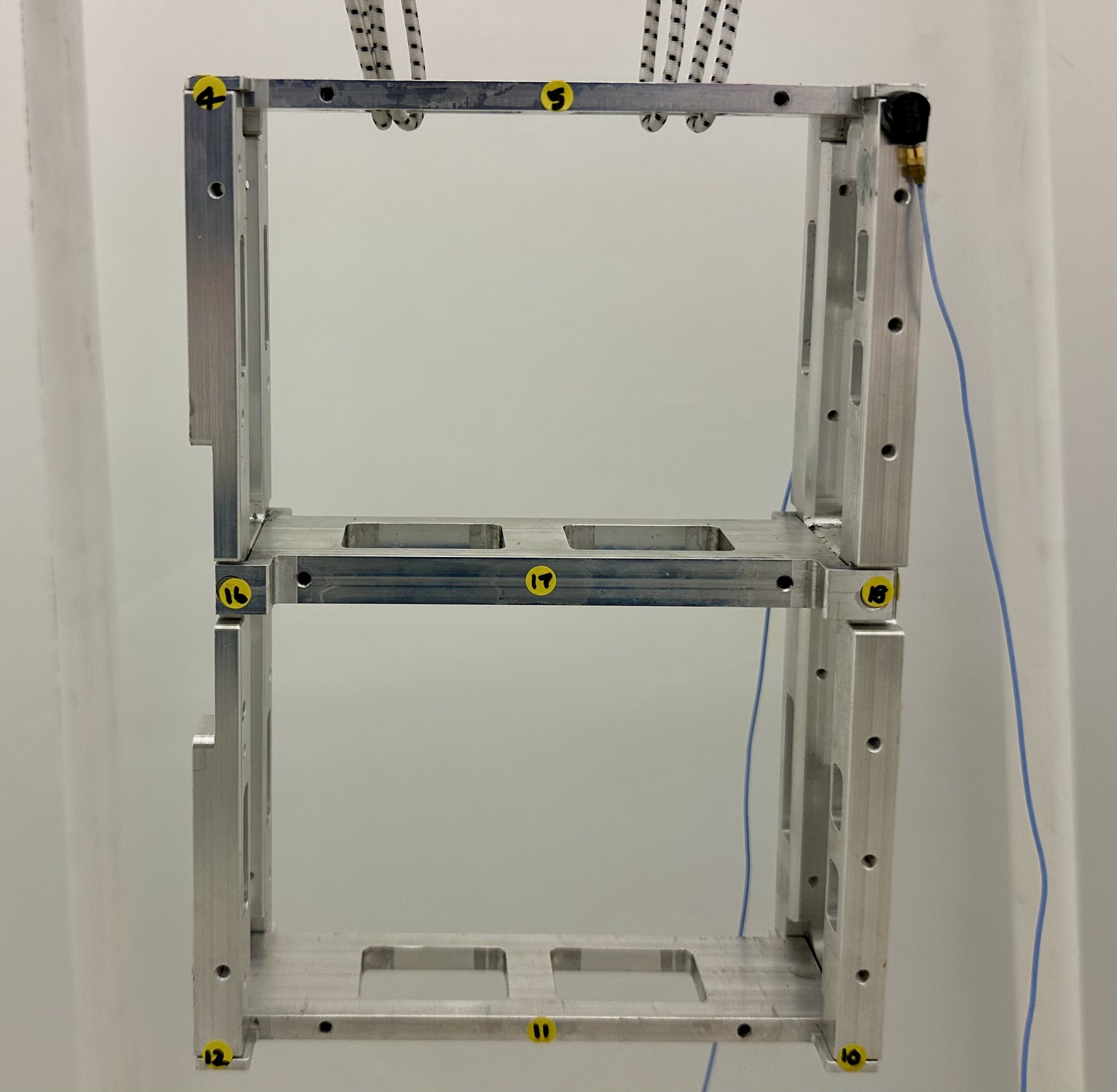

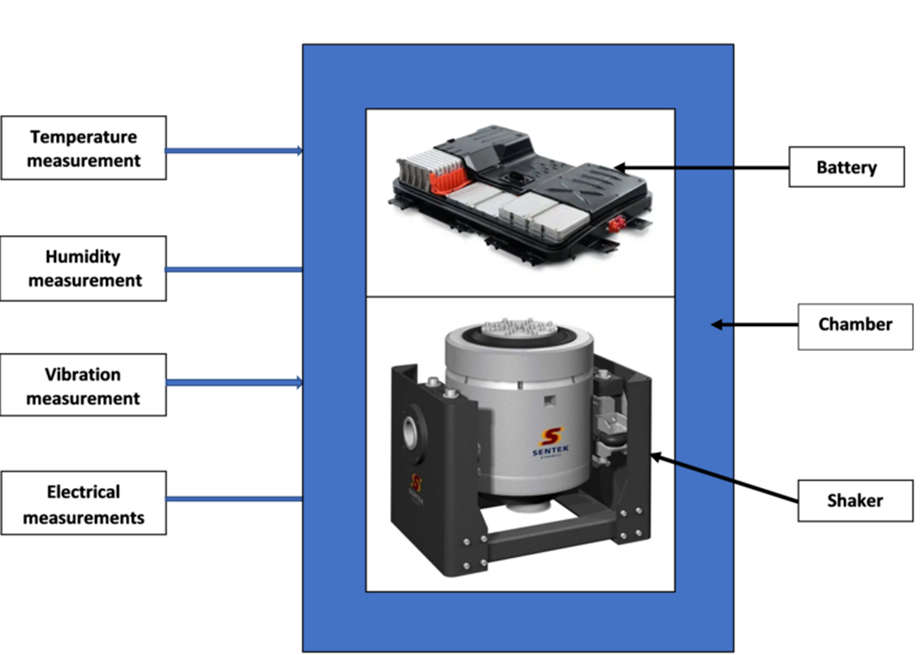

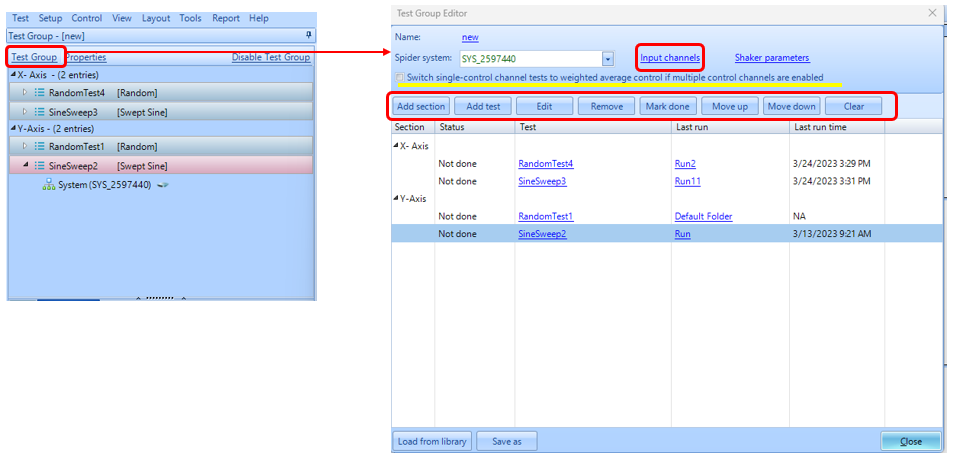

Vibration Test Systems

A complete vibration testing system consists of a shaker, power amplifier to drive the shaker, vibration controller, and accelerometer to feedback the actual acceleration. The vibration controller loads the test specifications from the user, and outputs a low-voltage drive signal to the amplifier, which then scales the signal to a high-power drive to the shaker. The shaker then excites the test object and accelerometer, which returns a control voltage signal to the vibration controller, completing a closed-loop feedback control system. The controller then adjusts the drive to the shaker as needed, keeping in line with the target profile.

Three-axis vibration testing system featuring the Spider-80M MIMO vibration controller.

Vibration testing is used in many different industries, such as automotive, aerospace, avionic, telephonic, consumer electronics, military equipment, and more. See the links below to learn more about Crystal Instruments’ offerings in vibration controllers, and our sister company Sentek Dynamics’ offerings in shaker systems.

Shaker Vibration Testing Applications

Shaker Vibration Testing Products

Vibration Testing Capability

Sine, Random, Classical Shock, Transient

Time Wave Replication, Kurtosis Control

Sine on Random, Random on Random

Shock Response Spectrum Analysis & Synthesis

Shock & Drop, Halt/Hass Application

Complete Alarm, Limit & Notching Protection

Free Article Download

Download An Introduction to Vibration Testing Systems (courtesy of Sentek Dynamics).

Specifications & Standards Applicable to

Crystal Instruments' Vibration Testing Systems

Specifications & Standards Applicable to Crystal Instruments' Vibration Testing Systems (continued)