Linear and Angular Displacement Protection for Multiple-Exciter Single-Axis testing

Overview

This article discusses the concept and implementation of a unique safety feature for environmental testing with a focus on Multiple Exciter Single Axis (MESA) vibration testing.

MESA is a multiple exciter setup with all exciters arranged along one single axis. The unit under test is rigidly fixed to a shaker table for the majority of time. Current testing trends favor a high level and high frequency. The potential risk of over linear displacement or over angular displacement is increased. A shock test with a large displacement is especially risky. If this does occur, the UUT, shaker table, or shaker armature can experience damage.

The proposed Displacement Protection feature will monitor the linear displacement in the time domain of each shaker table. When the linear displacement exceeds the predefined tolerance, an alarm or abort can be triggered. The angular displacement between two shakers table can be derived from a dual shaker MESA testing configuration, with one linear displacement sensor deployed to each shaker. Then, the angular displacement can be monitored against the tolerance.

The Displacement Protection feature is based on highly accurate laser displacement sensors. Mounting the laser sensors is a critical step when adding devices to the shaker system. The current configuration allows the laser displacement sensors to be mounted under the shaker cover. The mounting applies to any MESA shaker configuration, vertical or horizontal. The reliability of the mounting and sensors are tested and confirmed.

The testing results validate the new linear and angular displacement protection concept. The proposed Displacement Protection feature adds an extra layer of safety to modern high-level testing.

MESA testing

MESA testing frequently used due to its higher force rating and extended shaker table size compared to a single shaker configuration. Larger and heavier Units Under Test (UUT) are accommodated. The following image displays a MESA system in the horizontal configuration for transverse testing.

The current control system and shaker in MESA configuration lacks adequate protection. For example, if one side of the shaker moves while the other stops, the controller may not detect the malfunction.

Even worse, if two sides of the shakers move out of phase in the low frequency range, the shaker armature can suffer damage. The controller does not have enough information to abort the test.

The cause of damage to the shaker is not acceleration, but strain, which results from force being applied to the armature.

The existing vibration control is based entirely on the acceleration response of the structure.

If the force or overturning moment of the shaker is measurable, these values can assist with control or serve as aborting signals.

The main objective is to acquire the force or moment signals. If the force or strain measurement is difficult to achieve, displacement measurements against limits will provide a certain level of protection.

Displacement Protection

The proposed Displacement Protection feature will monitor the linear displacement in the time domain on each shaker table. When the linear displacement exceeds the predefined tolerance, an alarm or abort can be triggered. A dual shaker MESA testing configuration with one linear displacement sensor deployed to each shaker allows users to derive the angular displacement between two shakers. Then, the angular displacement can be monitored against the tolerance as well.

Both linear and angular displacements are measured and calculated in real time. Thus, any alarm or abort will happen instantaneously and will protect the testing system from damage due to over or angular displacement.

Different setups of MESA shaker configurations

The following diagrams depict several typical MESA configuration scenarios. The diagram illustrates the deployment of laser sensors and the angular displacement calculation.

Vertical with 2 displacement sensors. Two displacement sensors are arranged to measure the two linear displacements. The angular displacement along the X-axis is derived from two displacement measurements.

Three displacement sensors can be arranged If two shakers in the vertical direction are driving a two-dimensional head expander or table. The Roll and Pitch rotation can be computed respectively two displacement sensors.

Horizontal push-push with 2 displacement sensors. The yaw rotation angle can be computed from two displacement sensors.

Another push-push arrangement is illustrated in the following diagram, with two shakers against each other.

A horizontal push-pull arrangement with two displacement sensors. The yaw rotation can be computed.

The displacement alarm or abort is applicable for a single shaker configuration. One displacement sensor is placed; thus, an angular alarm or abort is not available.

Laser sensor placement and mounting

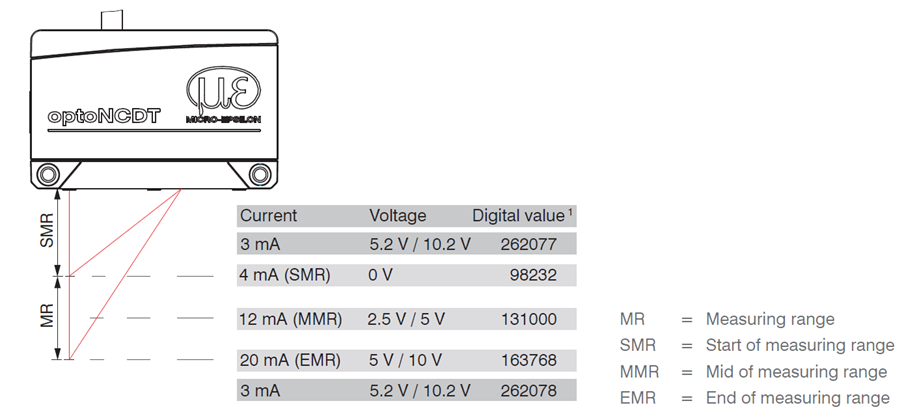

Laser sensors perform with high accuracy and precision. Install the sensor with the MMR onto the measurement surface.

Users can select a different range of laser sensors according to the installation dimensions to accommodate a shaker system.

In general, the laser sensor is mounted to directly measure each shaker table displacement.

Laser sensor calibration is required due to the impact of the installation. A side-by-side calibration is recommended to be performed with another laser displacement directly measuring the shaker table displacement. The correct sensitivity of the installed laser displacement sensor can be accurately calibrated with readings from these two laser sensors.

Testing cases

The laser sensors are deployed to a dual shaker system and several different types of tests are carried out. The results confirm that the Displacement Protection feature is practical and works as expected. It helps add one extra layer of safety to a large and expensive testing system.

The following screenshot displays the Displacement Protection feature in action for a MESA random test with shakers in the push-push configuration.

The calculated angular displacement tolerance of 2 degree is exceeded when the testing level is increases. The test aborts immediately after it is detected.

A MIMO shock displacement protection case is shown in the following screenshot. The test is aborted once the calculated angular displacement exceeds the abort limit.

In general, shock tests can result in large displacements. Dual shaker shock testing increases the potential of damage to a shaker system due to a rigid connection. The Displacement Protection system makes test running much safer.

Summary

The proposed Displacement Protection feature adds extra protections to testing equipment (including the shaker, armature, head-expander, slip-table and UUT). These protections are useful because the majority of UUTs are very expensive.