MIMO Vibration Testing

Multiple-Input Multiple-Output Vibration Testing

MIMO vibration testing has gained a huge momentum in the past decade with the development of multiple shaker table systems, the availability of Multiple-Input Multiple-Output (MIMO) vibration test controllers, and the readiness of the standards (e.g., Mil STD 810G method 527 and IEST DTE 022 working group recommendation). The Multiple-Input Multiple-Output (MIMO) vibration testing system includes the following:

MIMO Vibration Control - click to enlarge

MIMO Vibration Testing System Features

The multi-shaker system ranges from Multiple Exciter Single Axis (MESA), with 2 or more shakers involved, to Multiple Exciter Multiple Axis (MEMA), i.e., three axis translational shaker table, such as earthquake testing table, or 6 DOF Multi-Axis Shaker Table (MAST) table, etc.

Vibration Test Management

Vibration tests are managed through a MSSQL Server database. Signal files, test set-up, and UUT (machine) information are stored in the database. Users can search through previous tests using keywords, time, or date information. The database may be installed on local computer or a server on a LAN.

Spider Hardware System Management

A Spider system can consist of one or more Spider hardware front-ends. The user constructs the system by combining Spider front-ends detected on the same LAN. The software validates and displays hardware attributes of each Spider front-end.

- Spider-80M MIMO Vibration Test Controller: based on the efficient Spider-80Xi architecture and is dedicated to MIMO VCS control and MIMO structural testing applications.

Black Box Mode: Operate Without PC

A supported front-end can operate in Black Box mode which allows it to acquire data without a connected PC. In this mode, a PC is only used to configure the system before the test and then to download the data after the test is complete. During the test, the front-end can be operated according to a preset schedule.

Measurement Quantities

The user has an option to select a wide range of measurement quantities. Typical measurement quantities include acceleration, velocity, displacement, force, strain, torque, temperature, voltage, angle, phase, resistance, tacho speed, pressure, voltage, time, frequency, angular velocity, current, sound pressure, and mass.

Languages

English, Russian, Japanese, simplified and traditional Chinese are available. Languages can be switched without reinstalling software.

Continuous Data Recording

During vibration testing, all measurement input and drive signals can continuously record to a Spider-NAS or the internal storage residing in each front-end. Users can view and analyze data files with Crystal Instruments Post Analyzer. The variable sampling rate can be enabled to simultaneously record slow-change signals together with high speed vibration data.

Monitoring Through EDM Cloud

All tests in EDM-VCS support status checks through EDM Cloud. With EDM Cloud support, users can set up any VCS test to upload live data or run logs for completed tests to a cloud storage space provided by Crystal Instruments, where data is securely stored in the user’s account.

The EDM Cloud website is located at https://cloud.go-ci.com. Users can access EDM Cloud from anywhere in the world to check the status of past and current tests. A secure login flow ensures the status can only be checked by authorized personnel with proper credentials. Multiple logins for accessing the same Cloud account is available.

Visit Sentek Dynamics Three Axis Shakers

In the real world, structural vibration testing requires excitation from sources in all directions. To simulate a real-world vibration environment, vibration testing must be performed simultaneously in more than one direction. MIMO vibration testing is necessary for many applications, such as large structure testing with a single shaker requiring extensive fixturing, large structure testing with a single shaker providing insufficient force, or tests requiring simultaneous multi-axis excitation (translation only, or with rotation). MIMO vibration testing is recommended when SDOF testing is inadequate to properly distribute the vibration energy required to satisfy the specification.

MIMO vibration testing with simultaneous multiple direction excitation decreases the overall testing time by eliminating the time required to change the fixing of the DUT to the table and change shaker orientations (e.g., from vertical to horizontal). In general, MIMO vibration testing provides a distribution of vibration energy to the test article in more than one axis in a controlled manner without relying upon the dynamics of the test article for such distribution. The physical configuration of the test article is such that its slenderness ratio is high, thus Single Exciter Testing must rely upon the dynamics of the test article to distribute energy. For large and heavy test articles, more than one exciter may be required to provide sufficient energy for the test item. MIMO vibration testing allows more degrees-of-freedom in accounting for both impedance matches and in-service boundary conditions of the test article.

|

|

|

|

|

|

|

|

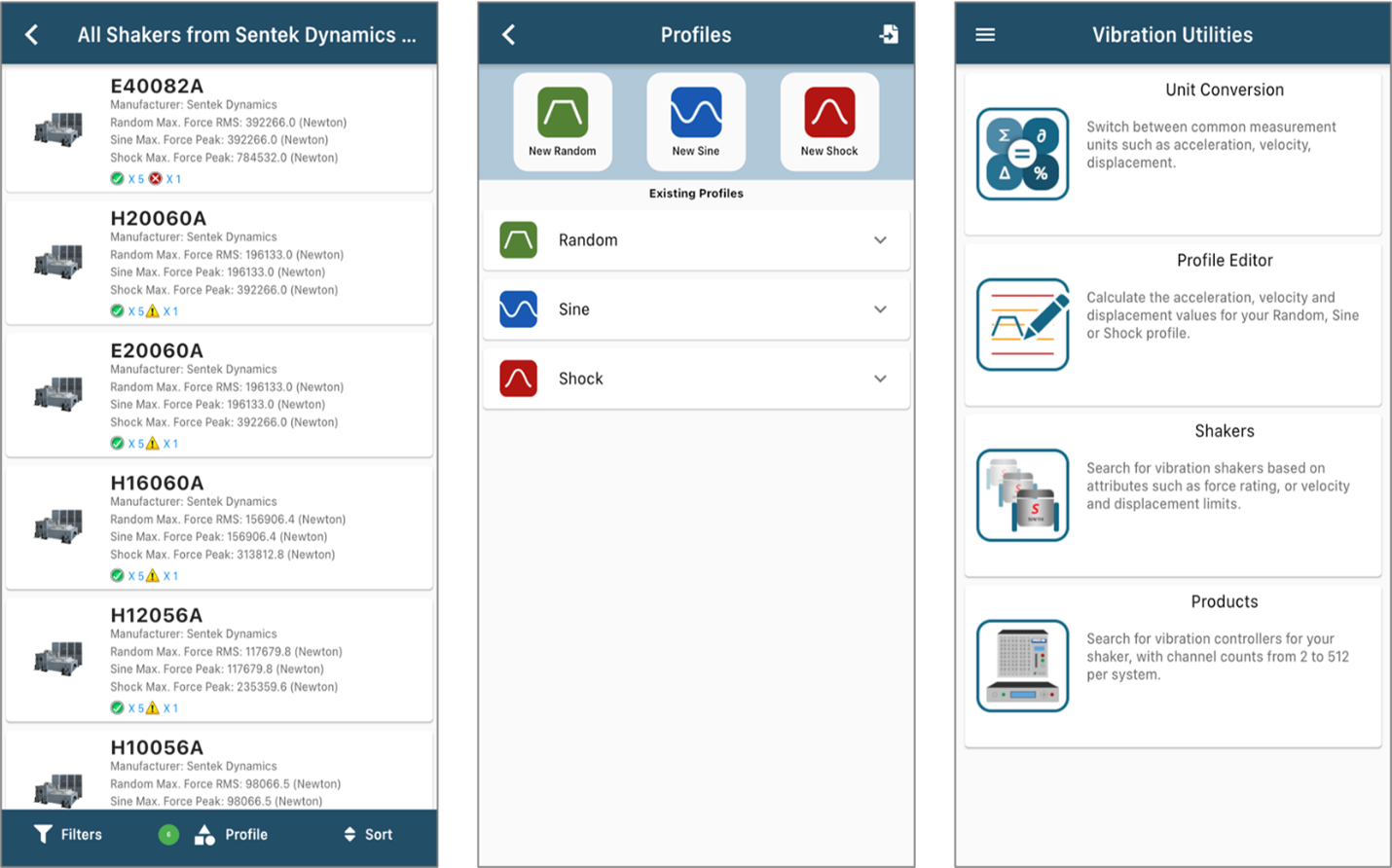

Vibration Utilities App

Crystal Instruments in partnership with our sister shaker company Sentek Dynamics provides users with the Vibration Utilities mobile app on iOS and Android. This app provides calculation features for sizing your vibration profile (Random, Sine or Shock) and searches through our catalogue of shakers and controllers for the best fit.