MESA Vibration Control

Multiple-Exciter Single-Axis Vibration Testing

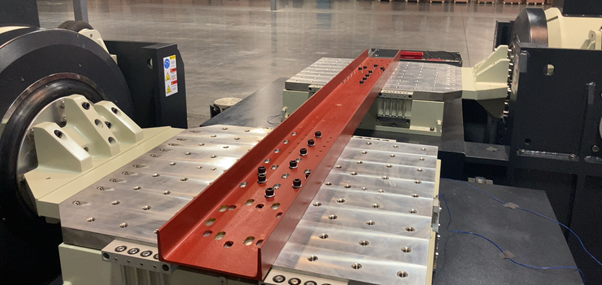

MESA vibration tests are specifically required when the unit under test is too heavy or too big and exceeds the capabilities of a single shaker. In a MESA vibration test, multiple shakers provide excitation to the test specimen in a single axis. Different relations like same magnitude and phase for drives, different phase for drives, different magnitude and phase for drives, can be set for this MESA vibration test.

MESA Vibration Control - click to enlarge

MESA Vibration Testing System Features

MESA vibration tests are specifically required when the unit under test is too heavy or too big and exceeds the capabilities of a single shaker. In a MESA vibration test, multiple shakers provide excitation to the test specimen in a single axis. Different shaker configurations in the horizontal, i.e., Push-push, Push-pull, or vertical direction would require a MESA vibration testing system.

Spider Vibration Testing Hardware

A Spider system can consist of one or more Spider vibration test controllers. The user constructs the system by combining Spider vibration testing hardware detected on the same LAN. The software validates and displays hardware attributes of each Spider vibration test controller.

- Spider-80M MIMO Vibration Test Controller: based on the efficient Spider-80Xi architecture and is dedicated to MIMO/MESA vibration testing and MIMO structural testing applications.

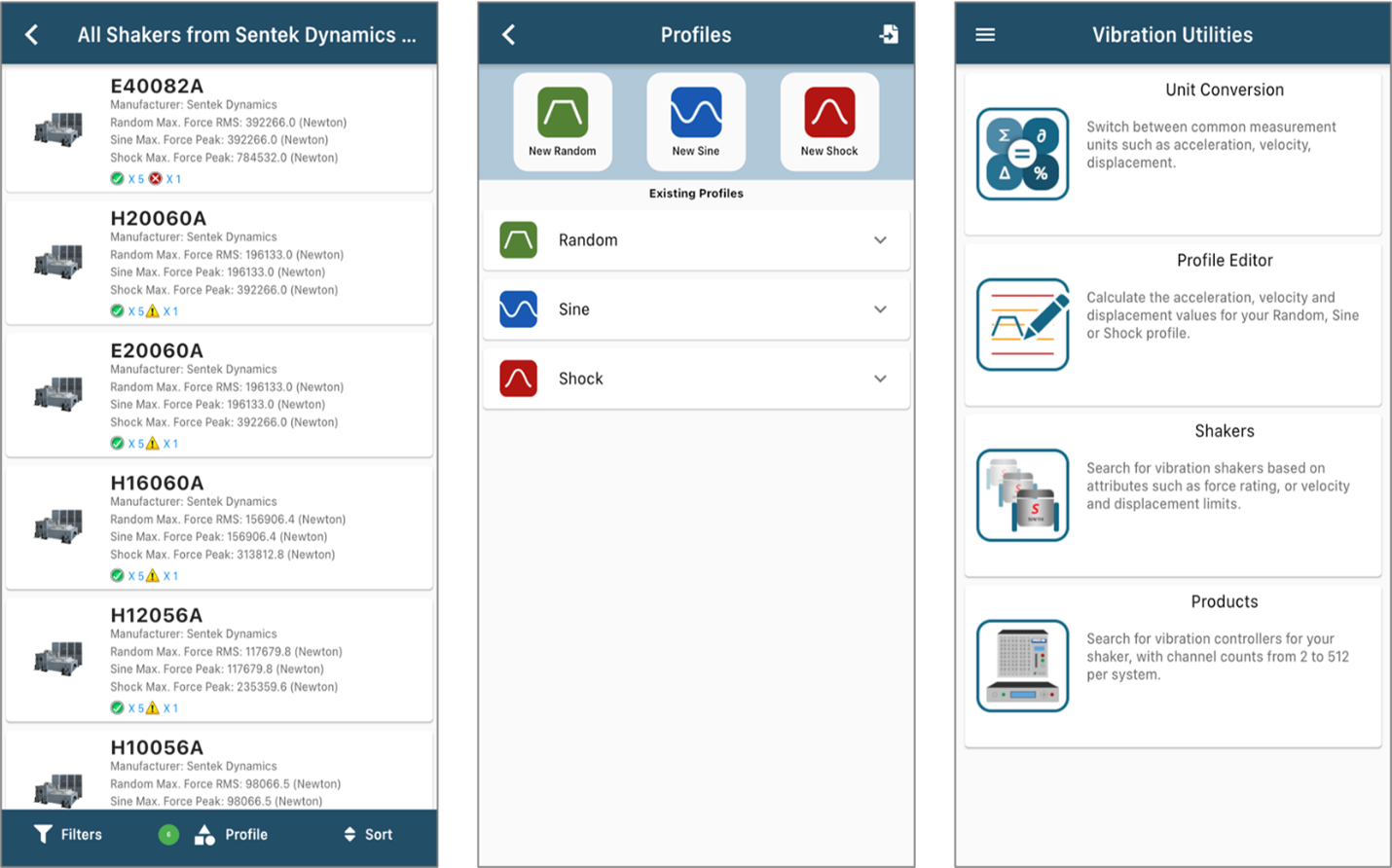

Vibration Utilities App

Crystal Instruments in partnership with our sister shaker company Sentek Dynamics provides users with the Vibration Utilities mobile app on iOS and Android. This app provides calculation features for sizing your vibration profile (Random, Sine or Shock) and searches through our catalogue of shakers and controllers for the best fit.

Running Test to Extended Frequency Range

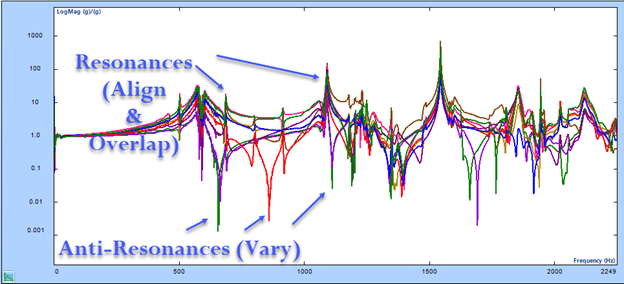

Various challenges hinder a successful vibration control test. The most crucial one is the limitation of structural dynamics of the system. The resonances and anti-resonances of the system cause the drive to reach its low or high limit respectively which can cause an issue with the control.

As illustrated from the above FRF signals from a head-expander, as frequency goes high, flexible modes come into the picture. The resonance frequencies from different locations are aligning, while anti-resonance frequency is varying location-wise.

To accommodate the resonance frequency, the corresponding drive will be dropped so as to maintain the control following reference target; while dealing with the anti-resonance, corresponding drive needs to be high which may be over the shaker input voltage limit. To address this issue, the weighted average control strategy could be used. Per localization nature of the anti-resonances, averaging will smooth out the valleys.

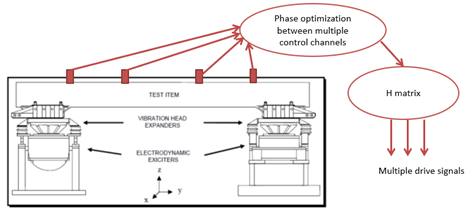

In MESA vibration testing, a unique algorithm is developed so that the phase from all control input channels are optimally synthesized based on the criteria of minimum energy of drives.

The phase optimization algorithm along with weighted average control strategy in a MESA vibration test helps combat the limitations to help achieve good control of the programmed test profile. This approach yields the best control performance even in the frequency range with many high resonances and anti-resonances.

Watch MESA Random & MESA Sine Vibration Testing

MESA Random Vibration Testing Video

MESA Sine Vibration Testing Video

Monitoring Through EDM Cloud

All vibration tests in EDM-VCS support status checks through EDM Cloud. With EDM Cloud support, users can set up any VCS test to upload live data or run logs for completed tests to a cloud storage space provided by Crystal Instruments, where data is securely stored in the user’s account.

The EDM Cloud website is located at https://cloud.go-ci.com. Users can access EDM Cloud from anywhere in the world to check the status of past and current tests. A secure login flow ensures the status can only be checked by authorized personnel with proper credentials. Multiple logins for accessing the same Cloud account is available.

|

|

|

|

|

|

|

|