Modal Testing Preparation Considerations

Download PDF | Jeff Zhao, Ph.D. - Senior Product Manager | © Copyright Crystal Instruments 2017, All Rights Reserved.Experimental Modal Analysis (EMA) is an important tool that is applicable for many structural vibration analysis situations. Fundamental aspects of performing a successful modal analysis include preparation, FRF data acquisition, modal parameter identification, and modal model verification.

In this technical note, the emphasis is to discuss the necessary technical details regarding the preparation of a successful modal test to acquire a set of FRF signals.

Typical Modal Testing preparation will include the following several aspects:

- Measurement locations/directions (DOFs). Measurement DOFs are arranged based on the mesh model created per the dimension of the structure under test. Each measurement signal is associated with a unique measurement DOF.

- Sensor selection. Sensors play an important role in acquiring high accuracy data. The selection of the sensor needs to be commensurate to the structure under test; meaning the size and sensitivity should match the size of the test structure and testing level.

- Support of the structure under test.The structure under test is usually suspended using bungee cords, with so-called free-free boundary conditions. It is also possible that sometimes the structure under test is already installed in its operating environment when being measured.

Modal Testing Preparation

The purpose of modal testing is to acquire the FRFs based on the mesh model of the structure under test. This step is crucial because the success of a Modal Analysis relies heavily on the quality of the measured FRF signals. Without top quality FRF data, no matter how advanced or powerful the modal parameter identification algorithm is, it is not possible to obtain reliable modal parameters.

From this point of view, modal analysis is in fact relying on measurement accuracy. To achieve this goal, careful testing, planning, and execution are required. Although parameter identification plays a relatively less significant role, it is still crucial to obtain the modal parameters.

Mesh of the Structure Under Test

Before starting data acquisition, the measurement degree-of-freedoms needs to be specified. The term of point is used to define one and each measurement location on the structure under test. At each point, there are three translational directions, X, Y, and Z which can be measured and are usually described by its + or -, X, Y, and Z coordinates in a Cartesian coordinate system. The combination of a point number and its direction, i.e., +16Z is called DOF.

Practically, there are also rotational degrees-of-freedom at every point. These are difficult to measure due to their nature, and are usually not considered. When a sensor is mounted in the opposite direction, it can be labeled as -X, -Y, or -Z. The following is one Geometry DOFs sample of a plate. At each point, 3 local directions are labeled.

During the majority of time, the structure under test is more complex than a simple plate. The Geometry feature of the Modal software will process this type of structure under testing using Components. Each component has its own origin and defined Euler angle. This allows the component to take use of its own local Cartesian coordinate system for directions.

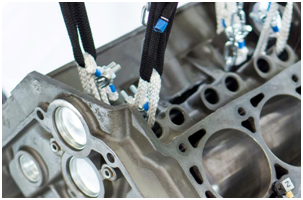

Sensor Selection

Running all types of tests, sensors play an important role in ensuring top quality measurement results. Nowadays, the majority of sensors offered are IEPE type sensors. The dynamic range of IEPE sensors is a factor that limits the quality of FRF measurements, so it must be ensured that the signal-to-noise ratio is as good as possible. IEPE sensors have +/- 5 V full scale voltage, thus a good rule to follow is to have the maximum voltage from the sensors above 0.5 to 1 V or so. Accelerometers should usually have a high sensitivity, e.g. close to 1000mV/g, or 500mV/g.

Since IEPE sensors have a fixed measurement range, it is necessary to keep force sensors with several sensitivities in lab equipment. With this variety, the force sensor with the proper sensitivity can now be chosen specifically for each test. This applies to impact hammers as well. It would be helpful to have a few impact hammers with different sensitivities and weights.

Another choice to consider is the usage of a few accelerometers roving over the structure versus using an abundance of static accelerometers covering the structure till all DOFs are measured. The choice here is often limited by the lab budget, but it should be made clear that for high quality results, it is necessary to use the latter approach for many structures. When roving accelerometers are used, the structure is likely to produce some time variance, and this is a mass loading issue.

There are also TEDS sensors available, i.e. IEPE sensors with built-in chips allowing the measurement system to read the model, unit, sensitivity, and more of each sensor.

Test Structure Support

The support of the structure under test needs to be decided before the test. This is often referred to as test boundary conditions. Typically, there are two possible support choices: free-free conditions, or as installed in operation. The main reason for choosing the first option, free-free boundary conditions, is that it is most likely to produce good measurements. When the structure is supported freely, the vibration energy introduced into the structure by the excitation stays in the test structure until it has naturally decayed due to the damping of the structure. On the other hand, when a structure is connected to the world around it, a lot of the excitation energy will transmit to the surrounding structures, which usually means it is more difficult to obtain good testing results. In order to make the best possible estimation of the modal parameters of a structure, the support of the structure under test needs to be free-free. For trouble-shooting purposes, modal analysis can be carried out on a structure installed into its normal operation environment.

Free-free boundary conditions are typically achieved by suspending the test structure on soft bungee cords or springs. Depending on the size and weight of the test structure, the bungee cords can be of many different sizes and stiffness. The suspending bungee cords should be soft enough so that the six rigid body modes due to the mass and geometry of the test structure and the stiffness of the bungee cords, is at less than a tenth of the first flexible mode of the structure under test.

This is particularly important when testing and suspending long slender objects. In general, these type of structures should usually be hung vertically, making it more likely that the rotational rigid body mode with rotation around the long axis of the object becomes sufficiently low. For long slender structures hung horizontally, there is an increased risk that the rotational rigid body mode will exhibit a relatively high frequency due to the small mass moment of inertia.

When supporting the structure under test using bungee cords, always avoid touching the structure with the bungee cords. This is likely to add damping to the structure. Instead, the structure under test should be hung using regular rope or thin steel thread, which is then connected to the bungee cords.