Rotor Balancing

Rotor Balancing is a type of analysis that compares the vibration profile with the rotation of a mechanical element to characterize inconsistent weight distribution around the diameter while calculating the amount and position of the weight necessary to offset the net imbalance.

Rotating elements of a system are a common source of unwanted vibration. Any mass that is not rotating around its center of mass will produce vibration. An everyday example of this would be car tires. Within every tire, small changes in density and thickness of the rubber cause one section to be heavier than the rest of the tire. This means that as the tire spins, that section will pull more than the rest, creating an imbalance.

This imbalance in the tire is offset with the addition of weights directly opposite this heavy spot. With the weight of the tire more uniformly distributed around the diameter, the vibration decreases and the car will run more smoothly.

The same general concept is used for industrial machinery. The main difference is the accuracy to which the weight is distributed and the types of rotating objects it is applied to. Rotating machinery is a common element of any facility. Motors drive fans, gear boxes, rollers, and many other types of mechanical systems.

Until recently, rotor balancing was a process that required a trained engineer. The process involved taking baseline measurements, graphically plotting on polar graphs, and calculating influence coefficients. Using Crystal Instruments’ handheld CoCo dynamic signal analyzer, the process has been largely automated. An operator can now perform a balancing operation simply and quickly using an automated process that instructs when and how to make changes to the system.

One Plane Rotor Balancing

The Rotor Balancing application is available in both operation modes of the CoCo: the Dynamic Signal Analyzer (DSA) Mode and Route and OnSite Mode Mode. This means the rotor balancing application runs as a standalone operation or as part of a routine maintenance program.

The balancing procedure consists of four steps. The first is to acquire a baseline vibration level. This characterizes the magnitude and direction of the vibration as the system is currently configured. Next, a known weight is added to a known location along the edge of the rotor. The rotor is spun again and a new reading is taken. The CoCo will use these two readings to calculate the influence coefficients and the weight required to offset the balance in the baseline reading. The known weight will be removed, and the correction weight will be added to the motor. A final spin-up of the rotor verifies that the vibration has decreased. The process can be repeated to further reduce the imbalance and vibration.

Figure 1: Balance Reading display while taking a measurement using the CoCo rotor balancing software

Figure 2: Enter the details of where and how much weight will be added to the rotating element

Figure 3: The operator is instructed to add the necessary weight to offset the imbalance at a position automatically calculated

Figure 4: Balance summary showing initial and final vibration vectors graphically

Key Analyzer Settings for Rotor Balancing

The following settings are used for impact hammer modal testing.

Tachometer Setup: A tachometer signal is required for balancing so the direction of the vibration vector can be characterized. Tachometer setup requires the threshold for the tachometer pulses to consistently cross the threshold level to ensure a consistent, reliable RPM measurement.

Number of Planes: The CoCo can perform 1- or 2-plane balancing. A 1-plane balancing operation would be used for a basic setup, with a single, narrow, overhanging rotor with minimal distance to the shaft support. A 2-plane balancing operation would be used for systems with a wider rotor, greater distance from the shaft support, or multiple rotors. The advantage of 2-plane balancing is the ability to identify and distinguish static and force-couple imbalances.

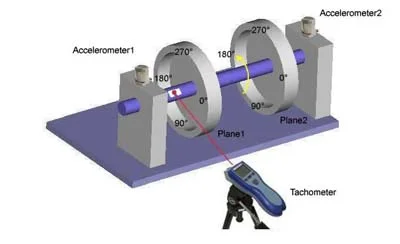

Movement: Directionality when measuring the angle of the vibration must be noted. In Figure 5 a laser tachometer is used. A piece of reflective tape is detected by the laser and represents the zero-degree point, the yellow arrow between the rotors shows the direction of rotation. The angles shown on the rotors show the "Against Rotation" angle measurements in which positive angles are counted in the opposite direction of the shaft rotation. For "With Rotation" measurements, the 90 and 270 degree position would switch places.

Trial Weights: The weight added to the rotor in the second step of balancing is not an analyzer setting, but is a key variable in the balancing process. The weight that is added must be large enough to noticeably alter the weight distribution of the rotor, but not so much that it stresses the system.

Figure 5: Balancing setup showing "Against Rotation" angle measurements

Recommended for Rotor Balancing

The CoCo-80X (and CoCo-90X) dynamic signal analyzer and vibration data collector are recommended by Crystal Instruments for Rotor Balancing. The CoCo series feature an intuitive interface, 2 to 16 channel configurations, and excellent product support to guide users through all their testing needs, including modal testing.