The accurate measurement of micro-vibrations is the first step of successful vibration contamination control. According to generic vibration criteria for vibration sensitive equipment, the RMS velocity of vibration criterion is from 50 to 3.1 μm/s (2000 to 125 μin/s). To measure such small amplitudes, high sensitivity and low frequency sensors must be used. Crystal Instruments provides the Wilcoxon WR 731 and PCB 393B31 accelerometers with the CoCo-80X data analyzer for this application.

Read MoreThe CoCo’s Save and Record functions are generally only discussed in the context of separate measurements. Although the Save and Record functions cannot be executed simultaneously, the CoCo is still able to store both the time waveform and FFT from the same set of original data. By exploiting the fact that FFT/block signals are always being buffered in the CoCo’s RAM, we can acquire the FFT signals while simultaneously recording the time waveforms to the SD card.

Read MoreSingle axis vibration control tests are widely used to qualify the behavior of the unit under test (UUT). If the UUT passes the test requirement then it provides confidence about the sustainability and durability of the test structure. However, sometimes excitation in multiple directions is required to test the robustness of the UUT which has led to the wide use of Multiple-Input Multiple-Output (MIMO) testing for the programmed test profiles. It is therefore important to make sure that the hardware setup allows for the unit to be tested in various configurations of single axis, dual axis, or three-axis. However, it takes long hours to manually change the setup because of the components (shaker setup, slip table, driving bar, fixture, etc.) involved.

Read MoreParadise Fireworks, the only black-powder fireworks manufacturer in Canada, recently rented a Spider-20E signal analyzer for some very unique tests. As a licensed explosion testing site in Canada, Paradise Fireworks was called upon to do some important blast testing for natural gas lines that lie beneath the small structures generally found in residential backyards. The goal of these tests was to define and quantify the dangers associated with having small structures (such as hot tubs and sheds) positioned above the junctions in these gas lines. To do this, Paradise would take pressure measurements from each blast using our high precision Spider-20E signal analyzer hardware in conjunction with our EDM DSA software.

Read MoreOn October 18th, 2020, a Bengkulu power plant in Western Sumatra Island successfully deployed a Power System Stabilizer (PSS) System and completed leading phase tests for Unit #1 and Unit #2 Generators, first of its kind in Indonesia.

The success of this project is a milestone for Indonesian power industry. The State Grid Corporation of Indonesia (PLN) highly praised the accomplishments of the engineering firm contracted to perform this test using Crystal Instruments’ CoCo-80 analyzer, and later awarded the firm with long term contracts.

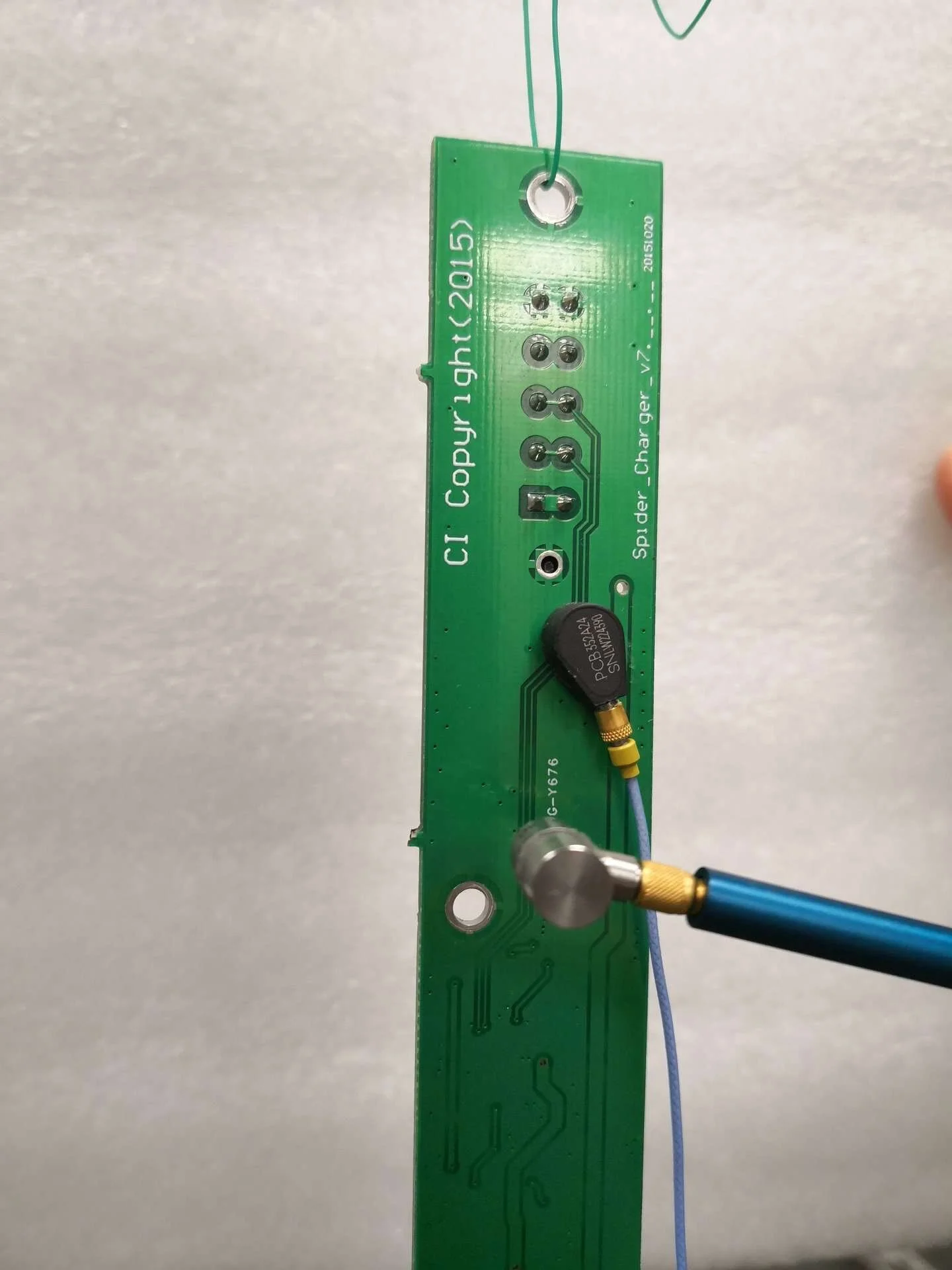

Read MoreIn this case, the modal characteristics of a Printed Circuit Board (PCB) is acquired by performing experimental modal analysis. A hammer impact test is carried out with a single teardrop uni-axial accelerometer to study the modal behavior. The roving excitation method helps users completely avoid the mass loading effect that might be introduced with a roving response procedure. Since the PCB is lightweight, the selected hammer and sensor were chosen because they weigh considerably lesser than the board itself. To excite the higher frequency modes, a hard tip is chosen. The hammer impact test module of the EDM Modal suite assists in executing this test.

Read MoreDual excitation shaker systems are commonly used to test long or heavy devices under test (DUT). When the device under test is very long or too heavy, a single shaker cannot perform the test because of oversized dimensions or a large driving force. Thus a dual excitation shaker system is arranged as the solution. Users can fix the longer sized or heavy DUT horizontally or vertically on top of a dual excitation shaker system. Common arrangements are horizontal push-push, push-pull, and vertical.

Read MoreLabVIEW is a visual programming workbench provided by National Instruments. It is used in a variety of applications for distributed testing, measurement, and control systems. When combined with powerful data acquisition systems like Crystal Instruments Spider systems, it can accept a wide range of inputs from a wide range of sensors to perform real time spectral processing. This combination also enables the deployment of large scale custom industrial and production systems.

Read MoreCrystal Instruments (CI) is proud to announce that we have reached an agreement with THP Systems located in Letchworth, UK. for the distribution of our products in the UK & Ireland.

THP Systems has been providing high technology solutions in the Aerospace, Automotive, Defense, Education, Electronics, Ground Transportation, Health & Safety, Industrial, Noise Leakage Detection, Package Testing, Renewable Energy and Vibration Testing markets.

Read MoreHead expanders are commonly used for vertical environmental testing. The purpose of the head expander is to extend the surface area of the shaker top to accommodate units under test (UUTs) with large dimensions for mounting and testing. One of the key parameters is the working frequency range associated with each head expander. The upper frequency is often used instead of the first resonance frequency of the head expander in vibration control tests.

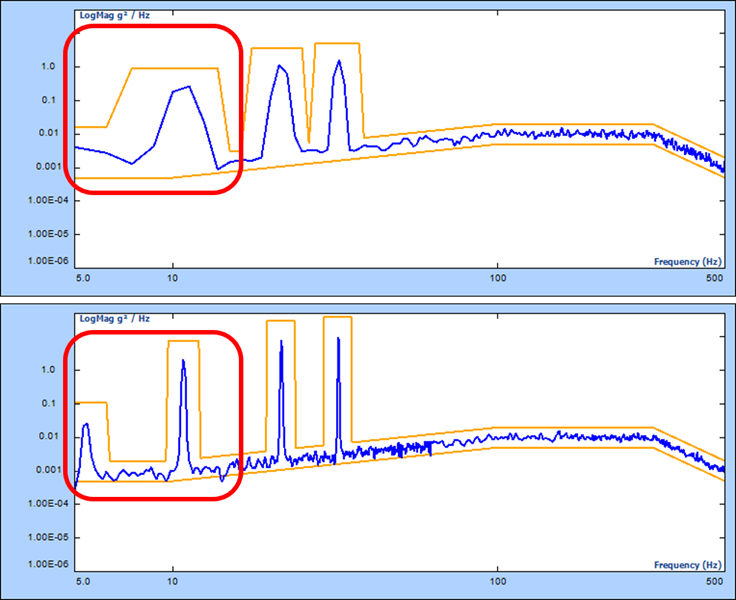

Read MoreIn this blog post, we will discuss the benefits of using Multi-Resolution, a feature available in Vibration Control Systems, to offer a better frequency resolution in the lower frequencies of the Sine-on-Random vibration spectrum. The same benefits are also applied to the general Random test, and Random-on-Random mixed mode test.

Read MoreOperating Deflection Shape (ODS) Analysis helps users understand the dynamics of the unit under test by animating the test structure’s vibration. As the term suggests, the structure’s deformation during operating conditions is visualized. This aids in understanding the forced response of the test unit.

Read MoreOff Route measurements are linked to machines in the database using a system called Job Management. When taking Off Route data, the measurements are stored under jobs and each job is assigned to a machine. The job-machine relationship is maintained after syncing the CoCo with VDS, so Off Route measurements are automatically associated with the correct machines.

Read MoreOn August 26, 2020, NASA selected Crystal Instruments to provide data acquisition equipment for the measurement of low frequency sonic boom events generated by one of their newest and most advanced aircraft, the X-59. The X-59 Quiet SuperSonic Technology (QueSST) aircraft is a research plane designed to study the effects of sonic boom events for companies developing supersonic aircraft for commercial travel.

Read MoreCrystal Instruments EDM 9.0 release combines the advantages of the Spider-20 product line’s small form factor and portability with the powerful modular and scalable Spider-80X/Xi systems during a single data acquisition application.

Read More